3D Print Farm: From Hobby to Business

Why Print Farms exist

Most print farms originate from passionate hobbyists eager to push the boundaries of what their 3D printers can do. However, working with a single printer quickly reveals its limitations. The low entry cost of 3D printers makes competition fierce, and sustaining a profitable business with just one machine is nearly impossible.

To thrive in this competitive landscape, print farm owners must provide added value. This could mean completing large orders quickly, offering custom CAD design services, or creating bespoke products tailored to client needs. With just one printer, breaking even is challenging; scaling up is essential for profitability.

As demand grows, so does the need for more printers. Over time, small operations evolve into print farms, offering customers a flexible and cost-effective alternative to traditional manufacturing.

Print Farms and their typical products

A print farm is a facility with five or more 3D printers producing parts or products at scale. The output typically falls into these categories:

- Personalized products sold through an e-shop to B2C end customers

- 3D-printed CAD models that B2B customers need to print

- Custom designs based on client specifications

For companies where 3D printing supports other operations, additional categories include:

- Parts for final products

- Prototypes for the design process

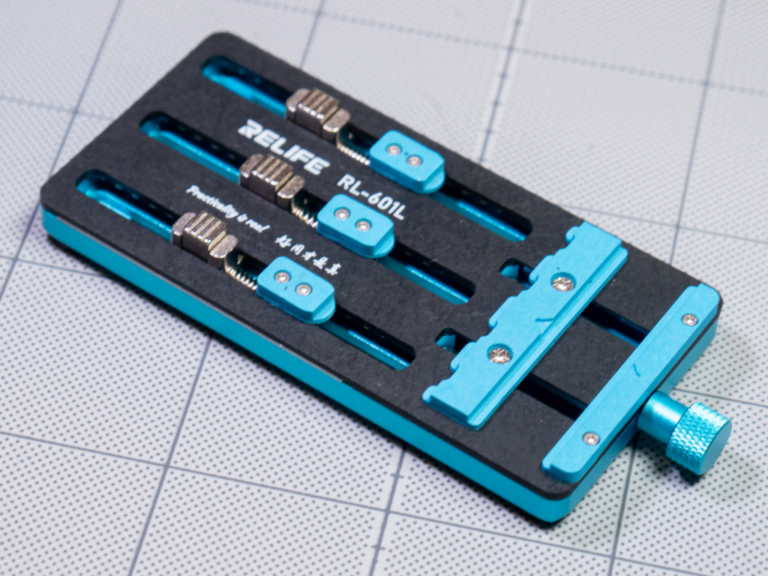

- Jigs, fixtures, and tools for manufacturing

Whether serving external clients or functioning as an internal resource, print farms operate on a different level than hobbyist setups.

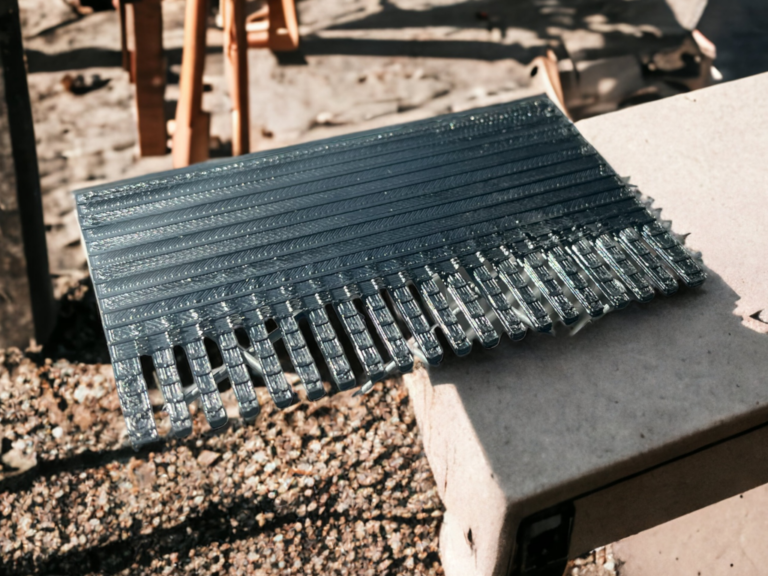

custom design developed based on B2B customer requirements - glass positioning pad used in construction

Hobby Printing vs. Proffesional Printing

The 3D printing industry is dominated by affordable printers designed for hobbyists. While these machines offer excellent value, they can struggle with reliability and scalability in professional environments.

Key differences include:

- Time Efficiency

- Hobbyists prioritize cost savings, often investing significant time tinkering with slicer settings to optimize prints.

- For professionals, time is money. Minimizing setup and print times is critical for profitability.

- Reliability

- Hobby printers often sacrifice durability for lower upfront costs, leading to frequent maintenance and downtime.

- Professional operations require machines that can handle high workloads reliably.

- Software Limitations

- Most slicers are designed with hobbyists in mind, emphasizing cost-saving over workflow efficiency. Lower costs of material are more important than user time needed to utilize methods of lowering costs. For print farms, optimizing for material savings can be time-intensive and counterproductive.

Scalability of Print Farms

Unlike traditional manufacturing, 3D printing farms scale easily due to the low cost of adding new printers. However, as print farms grow, bottlenecks emerge, particularly in software, workflow management and reliability.

For instance, hobbyists can afford to monitor and start every print manually. Professionals, however, need systems that enable continuous operation. Automating print job setups and scheduling ensures maximum utilization of printers, even outside business hours.

You should have more than one type of 3D printer to have advantage over your competition. 3D printers that you pick strongly affects how easily you be able to scale your operation in the future. The 3D printers, you have in your print farm, typically fall into these categories:

- Performance 3D Printers

- Good price-to-performance ratio and fast printing speeds but may be slightly less reliable. Example includes BambuLab 3D printers or other printers using Klipper for fast 3D printing

- Workhorse 3D printers

- May offer faster printing speeds, but their primary strength is reliability. They are desktop 3D printers or prosumer hobby printers like Prusa

- Slightly more expensive than performance 3D Printers.

- Speciality 3D Printers

- Purpose of these is to offer your customers advanced materials or stronger parts

- Typically 3D printers that can handle technical materials like Nylon or provide fiber-reinforced 3D prints

- Other technologies than FDM (FFF) Printers

- Typically SLS or SLA 3D printers

- SLA offers great visual quality but parts are not so strong

- SLS offers better visual quality than FDM and parts are stronger, but it is more expensive to operate and to buy these 3D printers

Pricing Strategies for Print Farms

Pricing products or services can be tricky. The simplest approach is to base prices on material and time costs. However, print farm owners can often command higher prices by offering specialized value.

Consider these factors:

- Exclusive Services: Are you handling sensitive customer data or maintaining long-term client relationships?

- Limited Competition: Can your customers easily find a similar service elsewhere?

- Cost Savings: Does your product significantly reduce costs for your customers compared to traditional manufacturing?

If the answer to any of these questions is “yes,” you have the leverage to set premium prices. Those unwilling to pay can turn to hobbyists or invest in their own printers, but professional-grade service justifies higher costs.

Custom Products: An Additional Revenue Stream

Idle printers represent lost potential. When not fulfilling client orders, many print farms diversify by selling custom products through e-shops.

Key steps to success:

- Start with a unique, in-demand idea.

- Design a CAD model that is:

- Easily recognizable

- Optimized for 3D printing

- Solving a real customer need

Limit material and production options to streamline costs and ensure efficiency. Additionally, consider selling your CAD designs on paid platforms, though be mindful of potential piracy.

Reducing Lead Times and Costs

The most lucrative opportunities for print farms often involve replacing traditional manufacturing for industrial clients. These high-value jobs demand fast turnaround times and low costs.

To maximize profitability:

- Minimize human labor costs by automating processes.

- Reduce print time to increase throughput.

- Save material to lower costs, especially for large-scale or high-volume jobs.

To automatically save 50% of material without reducing the parts strength, use Slicedog®. All the benefits of using your favorite slicer, 3D printer, and material remain yours—you just multiply them with an additional 50% material savings.