Structural validation for 3D printed parts

Make strength decisions before printing, not after failures.

Production benefit: Reduce unnecessary printing times.

Same printers. Same slicer profiles. No tuning.

Slicedog® validates strength of printed parts before printing. And automatically reinforces only load-critical regions using automated finite-element strength analysis.

Stop wasting 30–50 % of print time

Reduce printing time and increase your 3D printing throughput right now.

No new printers. No new slicer.

Slicedog® works right now with your current filaments, printers, slicer. Compatible with Bambu, Orca, Prusa, Cura and most major slicers.

Validated strength

Strength is validated before printing and material is used only where it carries load.

Today: strength is assumed

Default slicer profiles do not account for local stress concentrations

Strength is typically defined by experience and trial-and-error

Structural issues are discovered after printing, during testing or use

That’s fine until part breaks. Parts print longer while still being unsafe.

What changes with Slicedog®

You no longer guess where strength is required

Anisothropy of 3D printed parts is built-in

Strength is known before printing, not after failure

Knowing the actual stress and safety factor allows you to

confidently reduce material and print time.

Because you know the part will not break.

Same printer. Same profile. No tuning.

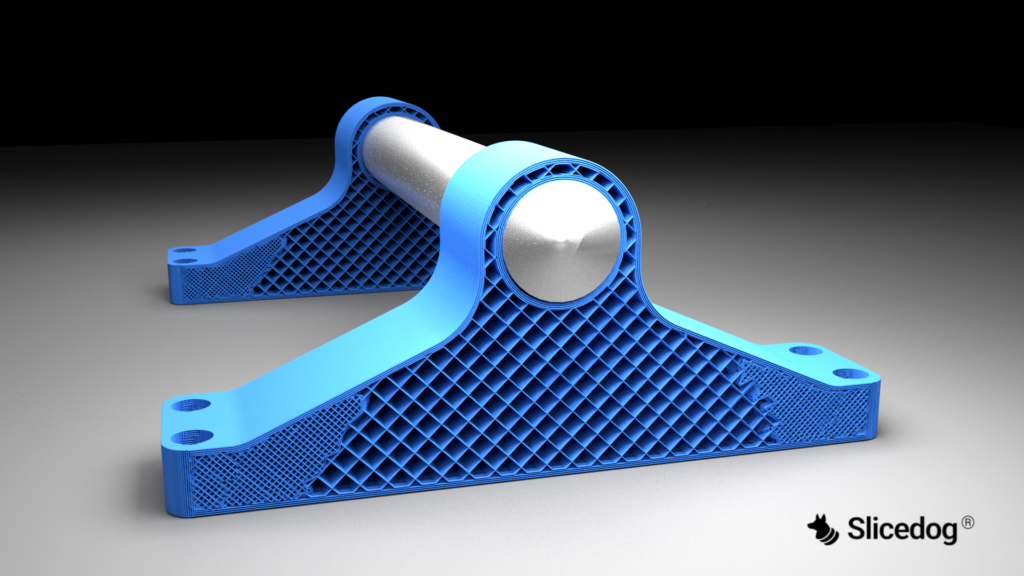

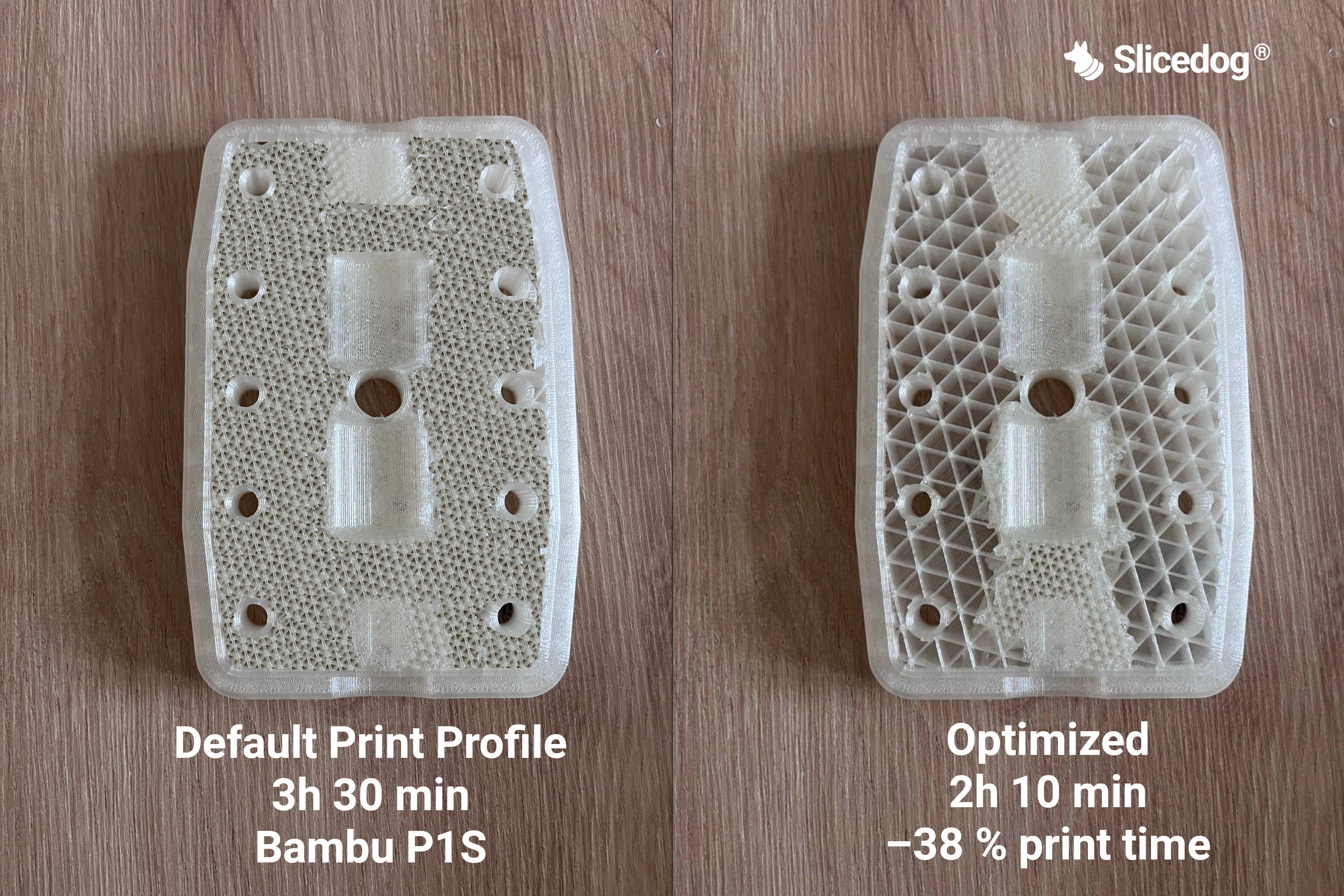

Optimized by Slicedog automatic finite element strength analysis, based on forces and fixed points defined by user. Still maintaining safety factor of 3 while printing 38% faster

Real results

Validated strength enables predictable savings.

Savings vary by part geometry, typically resulting in

30–70 % shorter print times once strength requirements are known.

In this production job, validated strength allowed a 37 % reduction

in print time across a 30-part run — saving 43 hours,

using standard printers and default slicer profiles.

When strength is known, material becomes optional

Slicedog validates part strength before printing using automated structural analysis.

You define forces and fixed points. The software predicts how the part behaves under load and verifies that strength requirements are met.

Once strength is known, Slicedog automatically reduces material in low-stress regions and reinforces only where it matters.

The result: predictable strength, lower weight, and typically 30–70 % shorter print times — not by tuning profiles, but by printing only what the part actually needs.

Automatic Strength Check

Automatic material use optimization

Automated finite element strength validation built for 3D printing

Slicedog uses a finite element–based strength model specifically designed for 3D printed parts.

Each part is automatically decomposed into perimeters, infill, and top/bottom regions, where each region has its own strength characteristics.

Strength is evaluated independently in X, Y, and Z directions for every region, reflecting the different strength behavior of perimeters, infill, and layer interfaces in real 3D printed parts.

Based on user-defined forces and fixed points, Slicedog predicts how forces propagate through the printed structure and identifies load-critical regions.

During optimization, material is redistributed to meet strength requirements with defined safety factor.

After optimization, the entire part is re-validated to ensure the target safety factor is achieved.

The strength model has been validated against real printed parts and physical load tests, not just synthetic samples — ensuring that simulation results match real-world behavior.

Validated by mechanical tests

Automated finite element strength

Pressure test of 3D-printed infill used to determine anisotropic strength characteristics (different strength in X, Y, and Z directions).

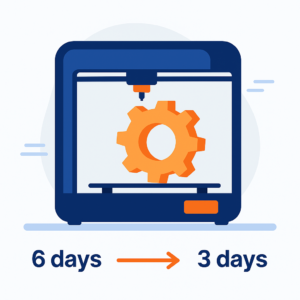

Cut days off your large print jobs

Whether you run your printers non-stop or take on large, complex jobs, long print times are often caused by overbuilt parts and uncertainty about strength.

By validating part strength before printing, Slicedog lets you confidently reduce material where it is not needed. A 6-day print can finish in just 3 days — without changing hardware, slicer profiles, or risking part failure.

The result: faster turnaround, freed machine capacity, and more predictable production.

Not only cut printing time, but cut design time too

It happens to everyone. You are about to finish your design, but you are not sure if the part is strong enough.

Instead of printing with confidence, you add material, thicken walls, or add supports — without knowing if it is actually necessary.

With Slicedog, you can validate part strength in seconds, automatically optimize material placement, and start printing right away.

No more trial-and-error prints. No more unnecessary design tweaks. Just a clear decision: this part is strong enough to print.

🚀 INCREASE YOUR PRINT CAPACITY — WITHOUT GUESSING STRENGTH

Ready to validate part strength before printing?

Slicedog helps you predict and validate the strength of 3D printed parts before printing, so you can stop overbuilding and stop guessing.