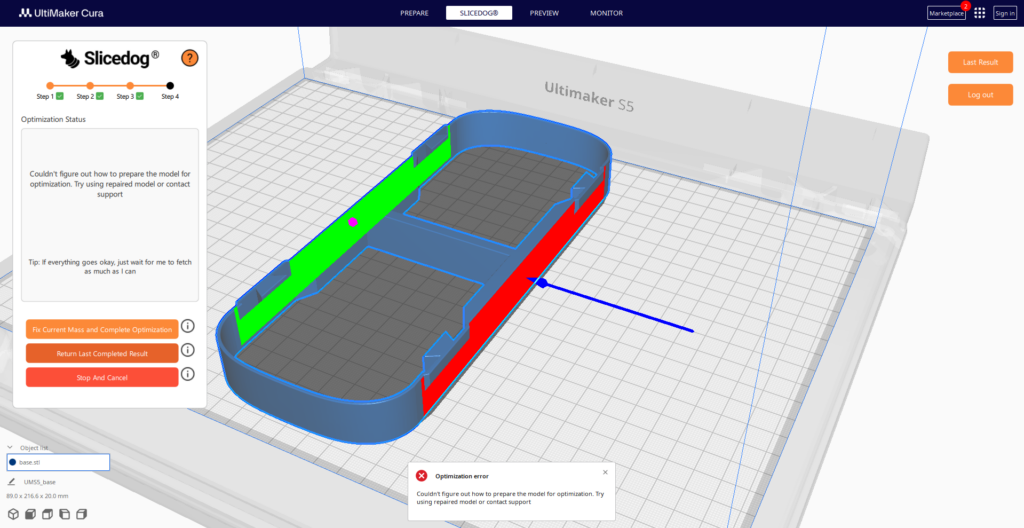

Model Preparation Error in Slicedog®

Slicedog® error message: Couldn’t figure out how to prepare the model for optimization. Try using repaired model or contact support

What happened

Slicedog® is built on finite element method (FEM) principles — the same foundation used in professional engineering software for structural analysis and optimization. As with any FEM-based tool, it’s important to understand that some models and geometry types present challenges. Even the most advanced FEM software may encounter problems with meshing or analysis on certain geometries, and the same applies to Slicedog® especially in its beta phase.

To help you get the best results, we’ve listed the most common issues and how to solve or avoid them:

- STL model is too complex

- Problematic features and parts of geometry of model

- Bad STL model quality

- Small features and parts of geometry

- Trouble in Forces and Fixed points definition (very rare)

1. STL model is too complex

Slicedog® works best with clean, simple CAD models — especially those designed to be strong and functional. Very detailed or sculpted models, such as organic shapes, figurines, or scans, often cause conversion or meshing failures. If your model is too complex, Slicedog® may not be able to convert it into a usable simulation object.

Models created using standard parametric CAD software (like Fusion 360, Tinkercad, OneShape, SolidWorks, Inventor, FreeCAD, etc.) usually work well. Try to avoid models from 3D scans or sculpting software.

2. Problematic features and parts of geometry of model

Even relatively simple CAD models may include details that prevent successful optimization. Watch out for these features:

- Text on the model – Remove text before optimizing

- Complex fillets or spherical features – Simplify curved features or disable them where possible

- Threads – Replace threads with simple holes. You can apply a “Force in Hole” to a simplified hole to simulate the presence of a bolt

- Thin walls – Thicken or simplify them to reduce risk of meshing issues

- Sharp edges – Soften or fillet edges to avoid narrow triangle formations

3. Bad STL model quality

Some STL files are simply too large (e.g., 20MB+) or contain internal errors such as intersecting triangles. To resolve this issue, try to export STL under different settings. Or to prepare your STL for use in Slicedog® try the following workaround:

- Export model as STEP – from your CAD software or by importing STL and saving as STEP. Or if you have just the original STL file, import it in CAD and export it as STL

- Open the STEP file in a slicer (e.g., PrusaSlicer, OrcaSlicer, Bambu Studio).

- Make sure it fits inside the printer’s build volume, or the slicer may export a blank STL

- Repair the STEP in Slicer if necessary

- Export it as STL again

- Load the new STL in Slicedog®

This process often removes small geometry issues and simplifies triangle mesh, making the file suitable for FEM optimization.

4. Small features and parts of geometry

Very small features and sharp transitions in your model can make meshing unstable or impossible. Meshing algorithms rely on clean, predictable geometry to create a finite element mesh — and complex edges make this process more difficult.

✅ Tip:

If the model has tiny holes, embossed logos, or intricate surface detail, try exporting a simplified version.

5. Trouble in Forces and Fixed points definition (very rare)

When assigning force or anchor points in the beta version, avoid selecting very thin or long triangles — this can cause unstable simulation.

✅ Tip:

Turn on the filter to “Hole” or “Cylinder” when defining your Force or Anchor points. This helps you select meaningful geometry (like actual holes or cylindrical surfaces) instead of problematic triangles.