Custom 3D Printing for E-Shops: A Guide for Print Farm Owners

Ever thought about turning your print farm into a revenue powerhouse with custom 3D printing? Selling unique, high-demand products through your e-shop can keep your printers running and profits growing. But where do you start, and how do you make it work efficiently? Let’s dive in!

Introduction

For print farm owners, leveraging custom 3D printing is an excellent way to keep printers productive while creating a steady secondary revenue stream. By offering custom 3D printed products through your own e-shop, you maintain full control over your inventory and brand. Additionally, you can expand your business by selling popular models on external platforms, creating a diversified income source.

This article explores how to successfully integrate custom 3D printing into your e-commerce strategy, maximize revenue, and improve visibility, with actionable tips tailored for print farm owners.

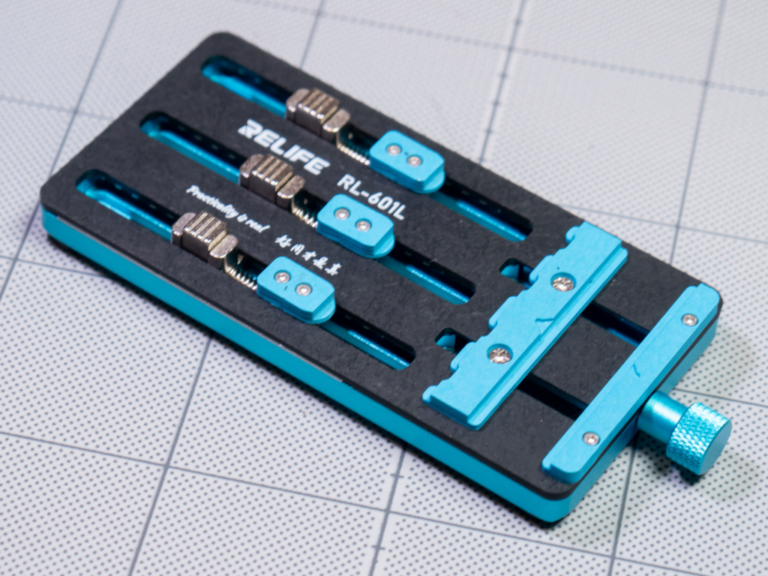

Utilize 3D printer during idle production hours. In this case 3D printing spare parts

Why Choose Custom 3D Printing as a Revenue Stream?

- Maximize Printer Downtime

Custom 3D printing fills idle production hours without requiring significant upfront investments. Unlike on-demand printing services, you can set predictable production schedules and enjoy higher profit margins. - Build Unique Offerings

Creating and selling unique, personalized designs allows you to stand out in a competitive market. Successful designs can generate high profit margins while appealing to niche audiences. - Boost Brand Visibility

Offering custom 3D printed products attracts traffic to your e-shop, improving your online presence and organic search ranking. Over time, these efforts can also generate interest from B2B customers seeking reliable 3D printing services.

How to Create Custom 3D Printed Products

1. Start with an Idea

Think about your target audience and their needs. For example:

- Parents seeking unique gifts for their children.

- Professionals looking for personalized office accessories.

- Enthusiasts who want something custom-made for their hobbies.

2. Design for Success

Develop CAD models that are:

- Easily recognizable: Stand out in a crowded marketplace.

- Optimized for 3D printing: Avoid over-complicated designs that are prone to failure.

- Validated for demand: Test your designs with small production runs before scaling.

3. Streamline Materials and Options

While offering variety is important, avoid overwhelming customers with too many options. Focus on a curated selection of materials and colors that are cost-effective to produce.

Popular Categories for Custom 3D Printed Products

- Consumer Goods

Products for daily use, such as:

- Personalized phone cases.

- Customized keychains.

- Unique gifts like figurines, ornaments, and engraved items.

- Spare Parts

Offer spare components for popular consumer products or DIY projects. 3D printed spare parts are especially valuable for discontinued products. - Niche Items

Target niche markets with items like:

- Custom cosplay props.

- Board game accessories and figurines.

- Listing your products on platforms like Amazon can increase visibility and sales.

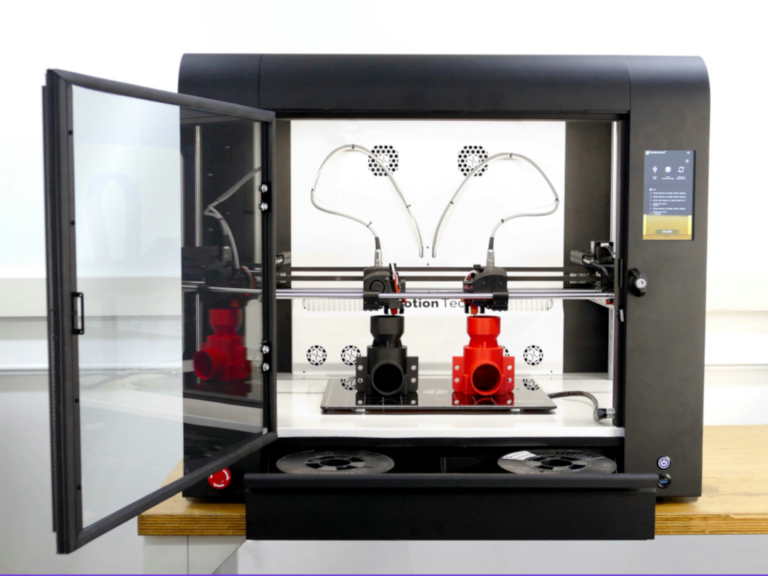

Board Game accessories, either as spare parts or as custom built figurines is popular custom 3D printed product

Technical Considerations for Custom 3D Printing

- Consistent Quality

B2C customers don’t care that the product is 3D printed—they care about quality. Invest in reliable printers and perform regular maintenance to ensure consistent results. - Efficient Production

Batch printing reduces downtime and improves efficiency. Tools like Slicedog® can further optimize production by reducing material usage by up to 50% and cutting print times, all while maintaining part strength. - Inventory Management

Keep popular items in stock to enable next-day shipping. Quick delivery is a significant advantage over hobbyist competitors.

Setting Up an E-Shop for Custom 3D Printing

- Choose the Right E-Commerce Platform

- Shopify offers an easy-to-use platform with customizable templates and integrations for marketplaces like Amazon.

- WooCommerce is a flexible, open-source solution for WordPress, though it may require technical expertise for advanced customization.

- A custom-built e-shop can provide ultimate control but is best suited for businesses with high turnover.

- Price Your Products Strategically

- For easily printable items, price competitively to attract customers.

- For unique, labor-intensive designs or advanced materials, set premium prices to reflect their value.

Test your pricing with small batches to find the sweet spot for your audience.

- Optimize Order Fulfillment

- Provide same-day or next-day shipping for an edge over competitors.

- Use automated systems to manage orders and streamline workflows.

Marketing Custom 3D Printed Products

- Broaden Your Reach

Don’t limit your audience to 3D printing enthusiasts. Use targeted ads (e.g., PPC campaigns) to reach specific demographics who might benefit from your products. - Upsell and Cross-Sell

Maximize revenue per transaction by offering related accessories or “you might also like” suggestions on your e-shop. - Leverage External Marketplaces

Selling on platforms like Amazon can significantly increase visibility. Integrations with Shopify or other platforms simplify the process.

Conclusion

Adding custom 3D printing as a secondary revenue stream can enhance your business in multiple ways. It keeps your printers productive, diversifies your income, and builds your brand’s online presence. Over time, the visibility gained from selling B2C products can attract new B2B customers, opening the door to even greater opportunities.

To maximize your efficiency and profitability, consider using tools like Slicedog® which reduces material usage by 50% and saves print time while ensuring the same or even better part strength. Contact us today to learn more about how Slicedog® can revolutionize your print farm operations.