Real results

Savings vary by part geometry. Typical range: 30 – 70 % printing time cut.

Real customer print job: 37 % faster, saving 43 hours on a 30-part run — no hardware or slicer changes, just using Slicedog® and default Bambu print profiles

As Featured On:

By using just necessary material you save print time

Slicedog uses automated structural strength analysis to optimize your print settings. You define forces and fixed points; the software verifies material strength and automatically adjusts infill where needed. It automatically optimzes perimeters, while low-stress zones use minimal material. The result: validated strength, less weight, and 30–70 % faster prints. By simply 3D printing using less material.

Automatic Strength Check

Automatic material use optimization

Save 50% of Printing Time

Reduce printing time and increase your printing farm throughput right now.

Works with your current printers

Slicedog works right now with your current filaments, printers, slicer.

Same quality, less time

Slicedog® reduces printing time without affecting quality

Boost your output without investing in new hardware

Default print profiles are overengineered — wasting time and material, costing you money.

Even with default slicer settings, Slicedog delivers immediate savings.

Slicedog ensures your parts are strong enough without wasting time or material, so you can increase revenue without increasing costs. No more manual tweaking or overbuilding for strength. And saving on default print profiles.

125% or more revenue

with 60% costs

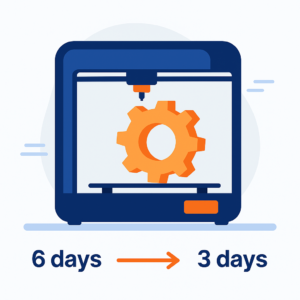

Cut days off your large print jobs

Whether you run your printers non-stop or take on big, complex jobs, Slicedog cuts your print times in half. A 6-day print finishes in just 3 days, freeing up your machines for more work — and more revenue.

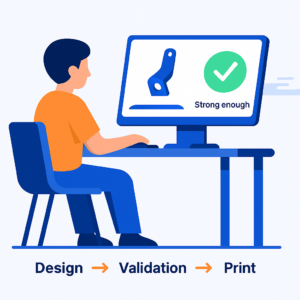

Not only cut printing time, but cut design time too

It happens to everyone. You’re about to finish your design, but you’re not sure if it’s strong enough. Instead of confidently printing, you spend extra time adding supports or thickening walls — without knowing if it’s necessary.

With Slicedog, you can validate strength in seconds, automatically optimize, and start printing right away. No more endless design tweaks. No more unnecessary prototypes.

🚀 INCREASE YOUR PRINT CAPACITY — SPEED UP YOUR ORDERS

Ready to cut 50 % off your printing time?

Boost your revenue by doubling your 3D printing throughput without buying new printers or hiring extra staff.

Start saving time and money with Slicedog today.